Alcohols

Ai Process Design & Construct State of the Art Gin Distillery for Alcohols Ltd.

Client:

Alcohols

Industry:

Food & drink

Project Site:

Rugby, UK

Objective:

Design & construct new gin distillation plant

Alcohols Ltd is a respected name in the UK spirits industry, known for producing premium-quality gin for both domestic and international markets. Operating one of the country’s oldest and most established distilleries, the company combines traditional distillation methods with modern process innovation to meet growing global demand. Their gin production arm supplies a wide range of branded and private-label products, and is recognised for its commitment to craft, consistency, and compliance. As consumer tastes evolve and export markets expand, Alcohols Ltd continues to invest in facilities that support scalable, high-efficiency distillation without compromising on heritage or quality.

Ai Process Scope of Works

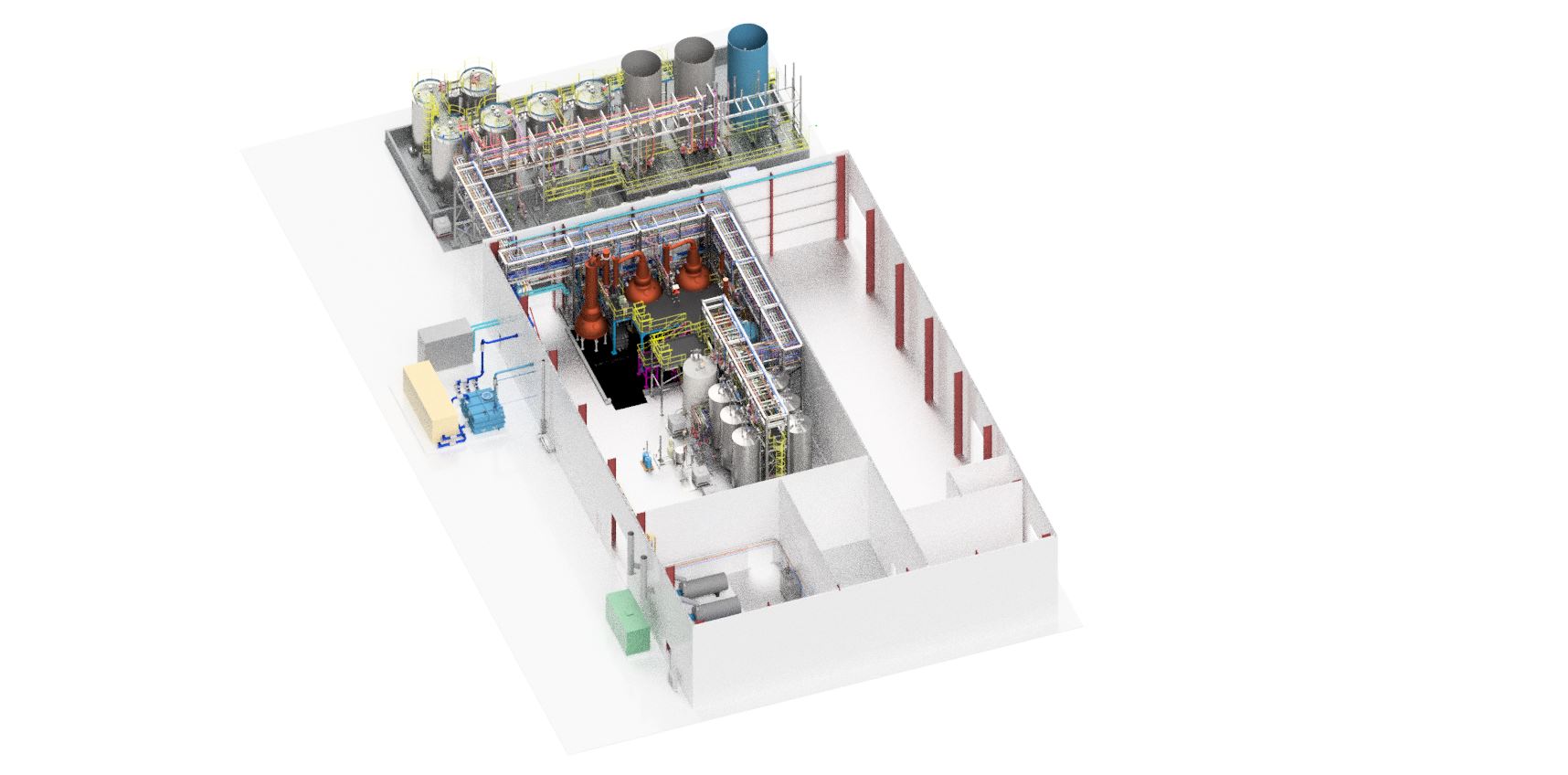

Ai Process undertook the comprehensive design and project management of the new solvent manufacturing site, ensuring the facility met Alcohols Ltd’s high standards. The project included the following:

- Front End Engineering Design Study (FEED Study)

- Risk assessment studies including HAZOP, DSEAR, PHA and SIL

- Energy usage assessment

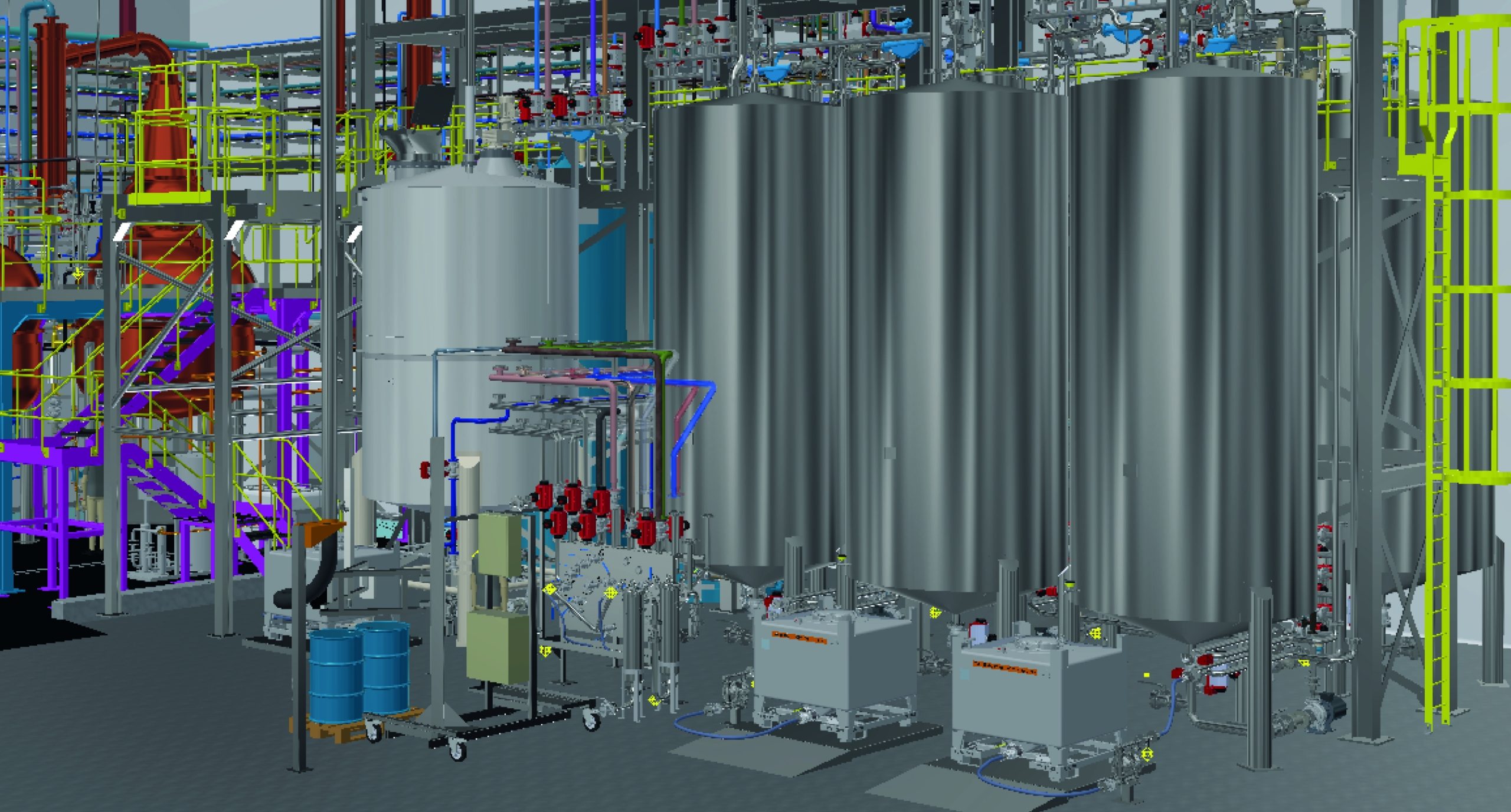

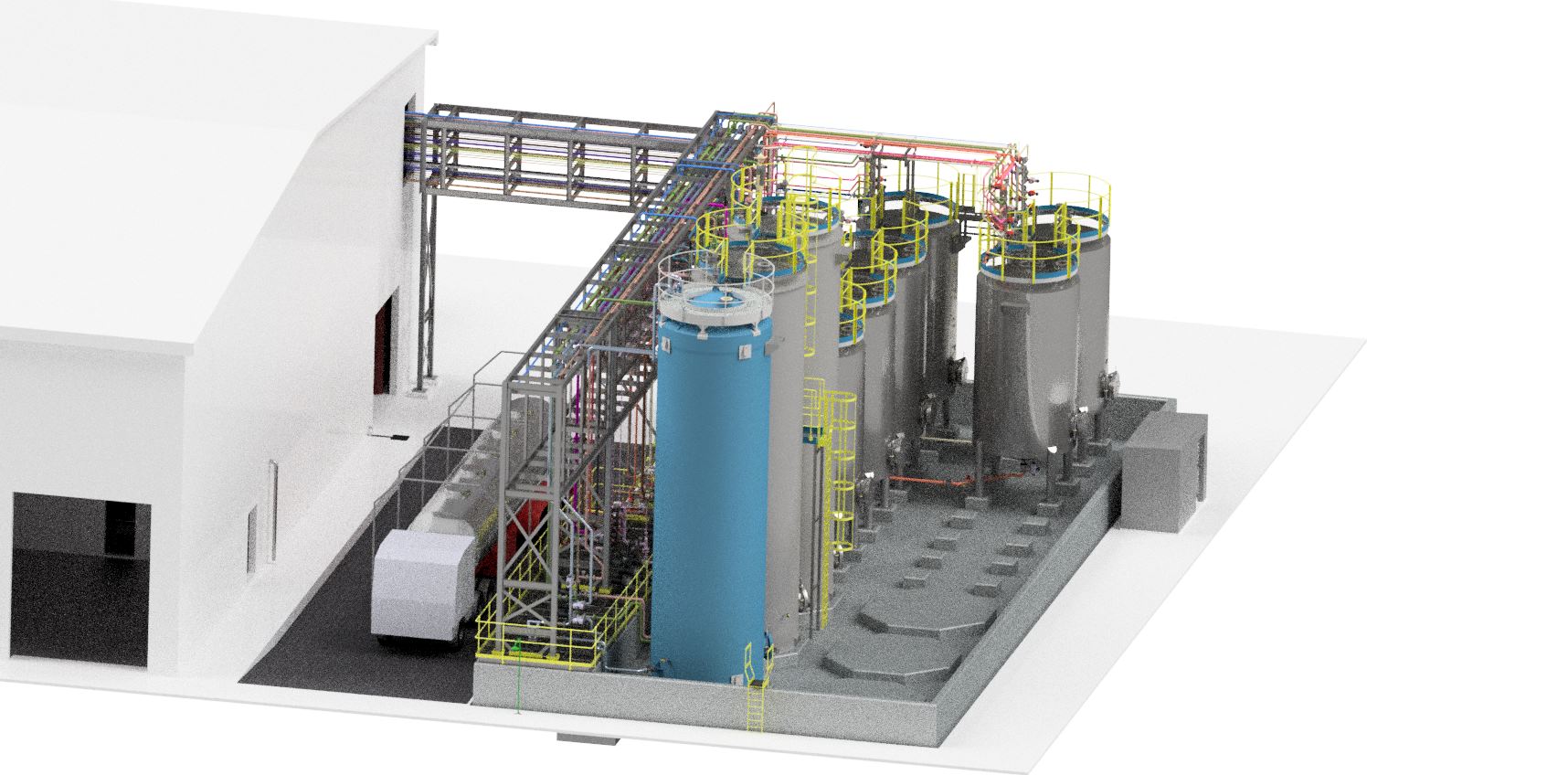

- Bulk distillery tank farm design and construction

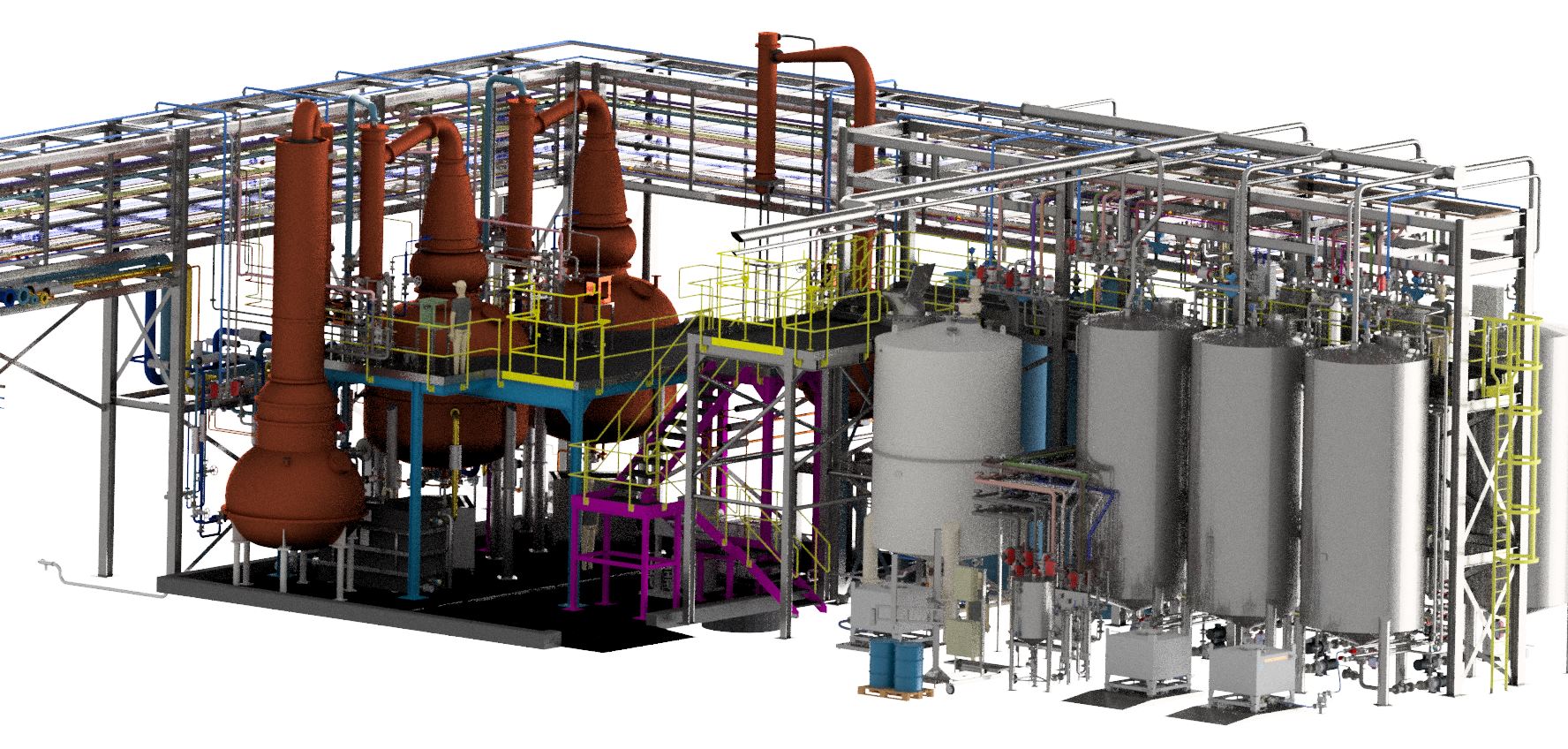

- Gin distillery production facility design and construction

- Supply of supporting process services and infrastructure

- Process control system

- Plant Commissioning and Handover

Outcome and Benefits

1. Enhanced Distillation Control & Product Consistency

Ai Process delivered a fully integrated gin distillation system with advanced process control, ensuring consistent flavour profiles and batch repeatability. The system enables fine-tuning of key distillation parameters such as cut points and reflux ratios, supporting Alcohols Ltd in maintaining the highest product quality standards for its premium gin lines.

2. GMP & Food-Grade Compliance

The facility was designed and built to comply with stringent food and beverage production regulations, including GMP (Good Manufacturing Practice). Hygienic materials, food-grade pipework, and cleanable surfaces were used throughout, supporting safe production of consumable goods and minimising the risk of cross-contamination.

3. Scalable Production to Support Brand Growth

The distillery was developed with the foresight to accommodate increased demand over time. The layout and process equipment were designed for scalable gin production, enabling Alcohols Ltd to meet growing market needs while reinforcing its position as a premium spirits producer both in the UK and internationally.

4. Food-Grade Standards and Contamination Control

Understanding the strict hygiene and safety standards required in the food and beverage industry, Ai Process specified materials and equipment suitable for food-grade environments. The design prioritised cleanability, corrosion resistance, and product integrity — reducing the risk of cross-contamination and simplifying compliance with food safety regulations. This approach gave Alcohols Ltd added confidence in maintaining both quality and regulatory assurance.