Alcohols

Ai Process Design & Construct State of the Art Solvent Manufacturing Facility for Alcohols Ltd.

Client:

Alcohols

Industry:

Speciality chemicals

Project Site:

Rugby, UK

Objective:

Design & construct new solvent manufacturing facility including tank farm and process infrastructure.

Alcohols Ltd is a long-established leader in the UK chemical manufacturing sector, specialising in the formulation and distribution of high-purity solvent blends for pharmaceutical, cosmetics, coatings, and industrial applications. The company provides bulk and custom solvent solutions to a wide range of high-regulation industries. With a strong reputation for reliability and compliance, Alcohols Ltd prioritises safety, traceability, and adherence to environmental standards. The business is recognised for its rigorous operational controls and commitment to sustainable, high-quality chemical manufacturing at scale.

Ai Process Scope of Works

Ai Process undertook the comprehensive design and project management of the new solvent manufacturing site, ensuring the facility met Alcohols Ltd’s high standards. The project included the following:

- Front End Engineering Design Study (FEED Study)

- Risk assessment studies including HAZOP, DSEAR, PHA and SIL

- Energy usage assessment

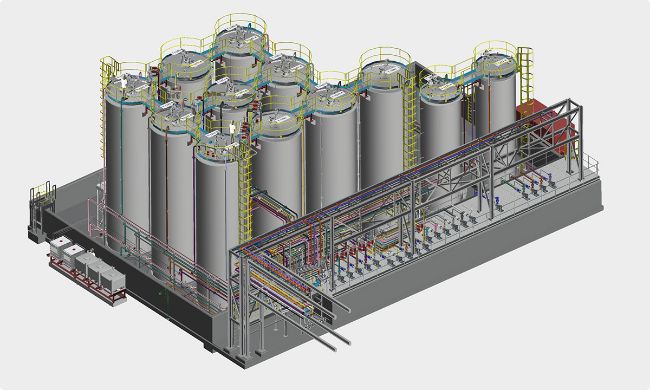

- Bulk solvent tank farm design and construction

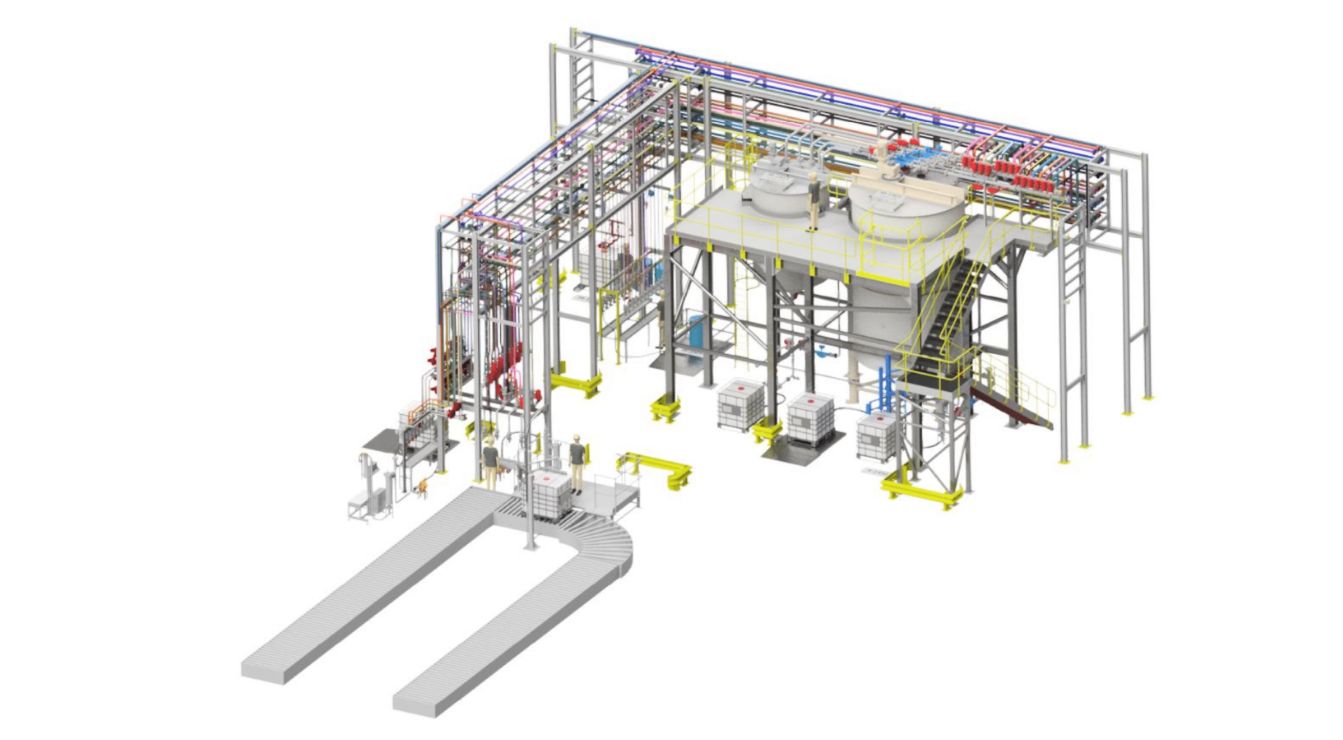

- Solvent manufacturing facility design and construction

- Supply of supporting process services and infrastructure

- Process control system

- Plant Commissioning and Handover

Outcome & Benefits

1. Production Optimisation

Ai Process significantly enhanced production efficiency at Alcohols Ltd’s new facility by implementing advanced process automation technologies and streamlined manufacturing workflows to increase throughput and reliability. Leveraging process simulation and modelling software, Ai Process optimised manufacturing processes to reduce variability and improve product quality.

2. Production Cost Reduction

Through the adoption of lean manufacturing principles, optimised process flow and cost-effective technologies, Ai Process helped Alcohols Ltd achieve substantial production cost savings. Optimised raw material usage, reduced waste, and improved maintenance protocols contributed to lowering production costs, enhancing the overall financial efficiency of the manufacturing facility.

3. Regulatory Compliance

Ensuring compliance with stringent industry regulations was a critical aspect of the project. Ai Process designed the facility to meet regulatory industry standards, incorporating advanced safety systems and comprehensive documentation processes. This proactive approach ensured ongoing industry regulation compliance, safeguarding Alcohols Ltd from potential legal and operational risks.

4. New Formulation Capabilities

The facility was equipped with versatile production lines capable of handling new product formulations. Ai Process designed flexible systems that could easily adapt to changing formulation requirements, enabling Alcohols Ltd to innovate and rapidly bring new products to market. This adaptability ensured that Alcohols Ltd could meet evolving market demands and maintain a competitive edge.