BASF

Redevelopment and Modernisation of BASF’s Construction Chemicals Facility at Swinton, Manchester

Client:

BASF

Industry:

Building & construction chemicals

Project Site:

Swinton, North Manchester, UK

Objective:

Redevelop and modernise BASF’s existing construction chemicals facility to increase capacity, efficiency, and compliance.

BASF Construction Chemicals, part of the global BASF Group, is a leading supplier of chemical systems and formulations to the construction industry. Their portfolio includes admixtures for concrete, ready-mix, and precast applications, along with high-performance construction systems such as sports and industrial flooring, exterior insulation, and specialised building products. With innovation and sustainability at the core of their strategy, BASF continually invests in facility upgrades and modernisation to maintain world-class standards in production, safety, and efficiency. The redevelopment of their Swinton facility was central to strengthening their UK operations.

Ai Process Scope of Works

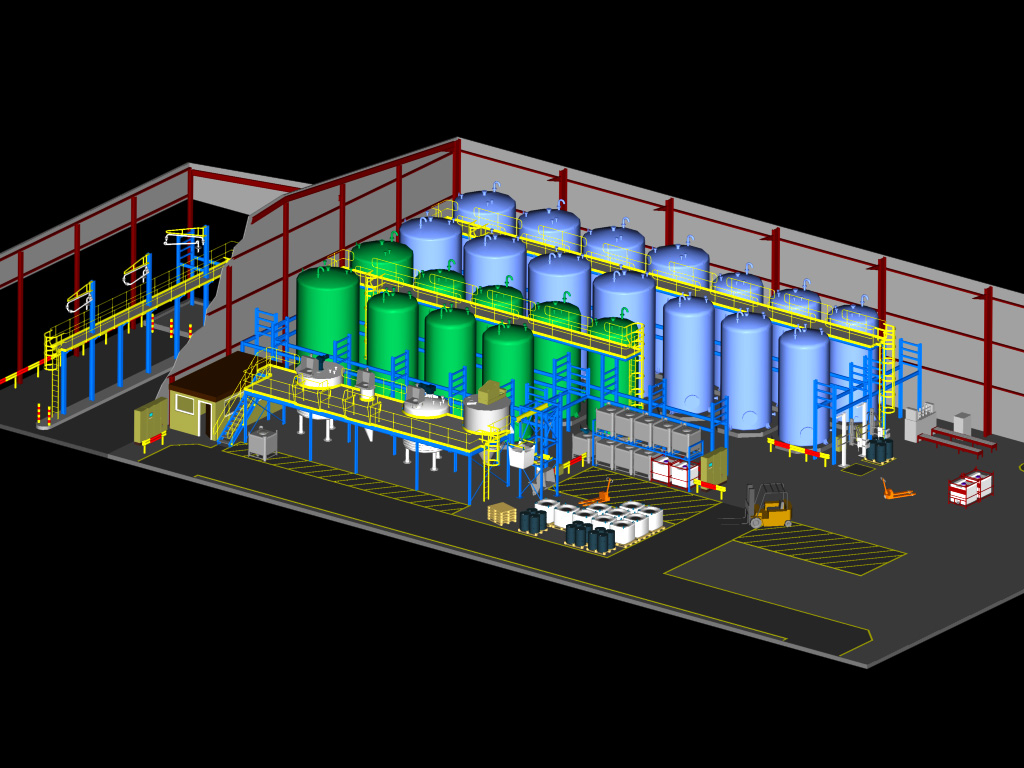

Ai Process was appointed to design, construct and commission the redevelopment of BASF’s Swinton facility. The scope of works included:

- Design and installation of a 740,000-litre indoor raw material and finished product storage facility

- Integration of high and low solids powder incorporation systems

- Implementation of a recipe-driven SCADA control system for process automation and accuracy

- Installation of IBC and container filling capabilities for efficient packaging and distribution

- Development of tanker loading and unloading facilities for both raw materials and finished products

- Full turnkey project management, covering procurement, construction, and commissioning

Outcome and Benefits

Increased Production Capacity

The upgraded facility provided BASF with significantly enhanced production capability, supporting higher output volumes without compromising quality. The integration of large-scale storage and advanced handling systems ensured the plant could accommodate growing market demand efficiently.

Improved Accuracy and Repeatability

Through the introduction of a recipe-driven SCADA control system, BASF achieved precise batch accuracy and consistency. Automated control improved repeatability across production runs, reducing errors and enhancing the reliability of finished products supplied to customers.

Enhanced Product Quality and Cost Efficiency

The modernised plant streamlined powder incorporation and mixing processes, directly improving product quality. By optimising raw material use and reducing waste, the redevelopment also delivered measurable cost efficiencies, supporting BASF’s long-term competitiveness in the construction chemicals sector.

Health, Safety, and Regulatory Compliance

Ai Process ensured the facility was designed and constructed in full compliance with the latest health and safety regulations. Safer loading and unloading systems, along with automated handling, reduced risks to personnel and provided BASF with a robust, future-proof operational environment.