Bostik

Ai Process Design, Construct & Commission New Solvent Tank Farm and Transfer System for Bostik in Stafford, UK

Client:

Bostik

Industry:

Adhesives & resins

Project Site:

Stafford, UK

Objective:

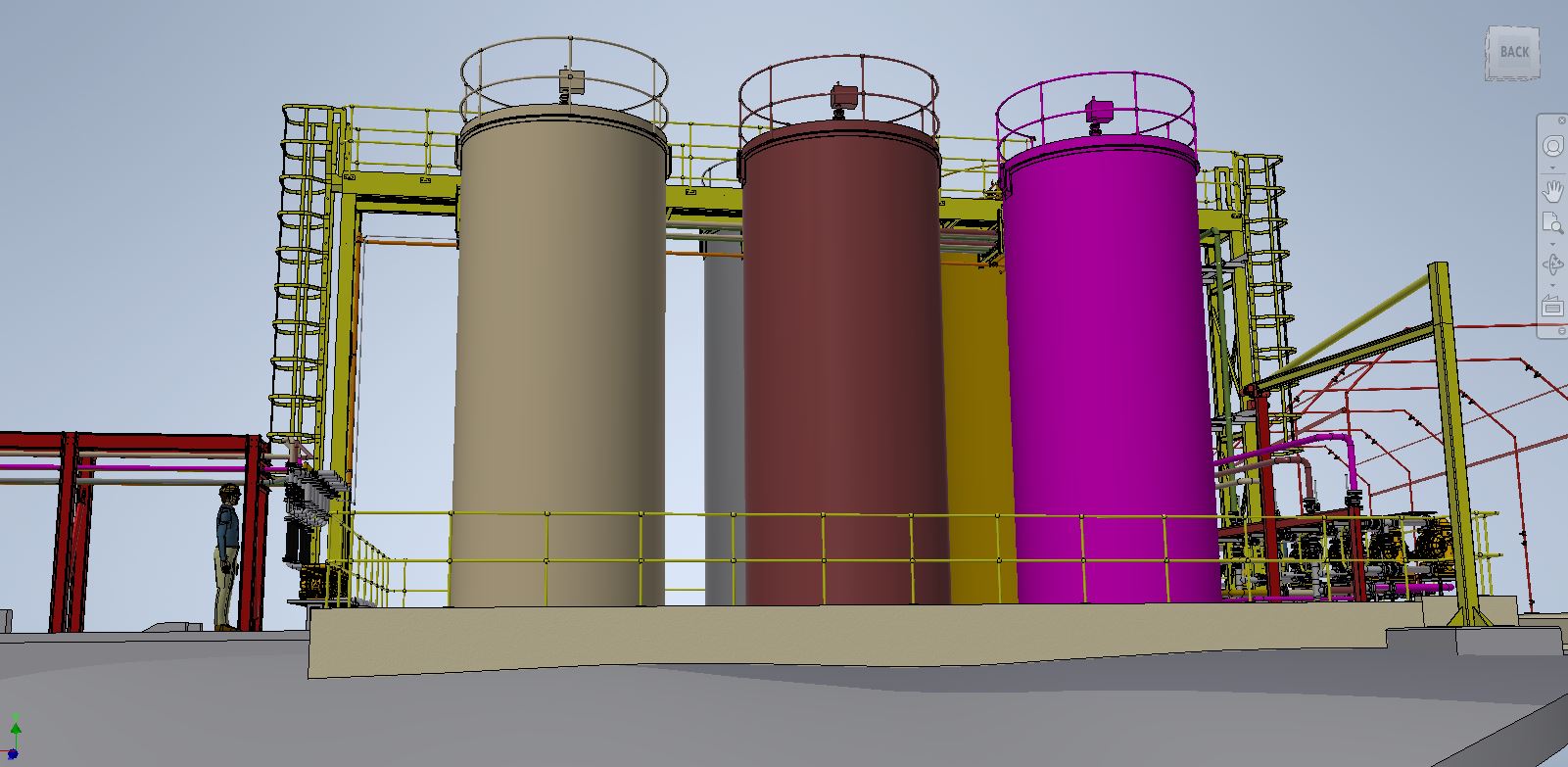

Design, install and commission a new solvent tank farm and solvent transfer system.

Bostik is a global leader in adhesive and sealant technologies, recognised for its innovative bonding solutions that serve construction, automotive, packaging, and consumer markets. Best known in the UK for products such as Blu Tack, the company has a longstanding reputation for delivering high-performance adhesives. With a focus on safety, sustainability, and compliance, Bostik continues to invest in modern manufacturing infrastructure that enhances efficiency and supports future growth. To strengthen its production capabilities in the UK, Bostik appointed Ai Process to design and manage the construction of a new solvent tank farm and transfer system at their Stafford site.

Ai Process Scope of Works

Ai Process undertook the role of Principal Contractor and delivered the project on a full turnkey basis. The scope of works included:

- Demolition of existing buildings and preparation of the site

- Civil works and bund casting for solvent storage integrity

- Fabrication and installation of new solvent storage tanks

- Construction of a solvent transfer pipe bridge

- Integration of process infrastructure, including pumps, valves, and controls

- Installation of sprinkler and vapour recovery systems for fire protection and emissions control

- End-to-end project delivery, covering detailed design, procurement, cost control, project management, and commissioning

Outcome & Benefits

1. Increased Production Capacity

The modern solvent tank farm increased Bostik’s overall production capacity and flexibility. The enhanced storage and transfer infrastructure allows for faster material throughput, reduced lead times, and improved efficiency in order fulfilment. Optimised raw material handling also minimises waste, improving long-term cost efficiency.

2. Operational Efficiency & Automation

Ai Process integrated automated transfer, dosing, and control systems, reducing manual handling and human error. The recipe-driven SCADA platform ensures consistent, repeatable solvent transfers, improving operational efficiency, traceability, and process reliability across the tank farm.

3. Regulatory Compliance & Environmental Protection

The new solvent tank farm was designed for regulatory compliance with ATEX, and UK Health & Safety Executive, including HSG 176. Comprehensive risk assessments (HAZOP, DSEAR) and vapour recovery systems ensured safe operations, reduced emissions, and strengthened Bostik’s sustainability credentials, supporting both environmental and corporate compliance goals.

4. Minimal Disruption to Operations

The project was delivered in carefully phased stages, allowing Bostik’s Stafford site to maintain operational continuity throughout construction. This turnkey approach minimised disruption to manufacturing schedules and ensured a seamless transition to the new solvent tank farm.