Jotun Paints

Ai Process design & project manage the installation of two new industrial paint mixers and bead mill including process infrastructure at Jotun Paints (Europe) Ltd

Client:

Jotun

Industry:

Paints, inks & coatings

Project Site:

Flixborough, UK

Objective:

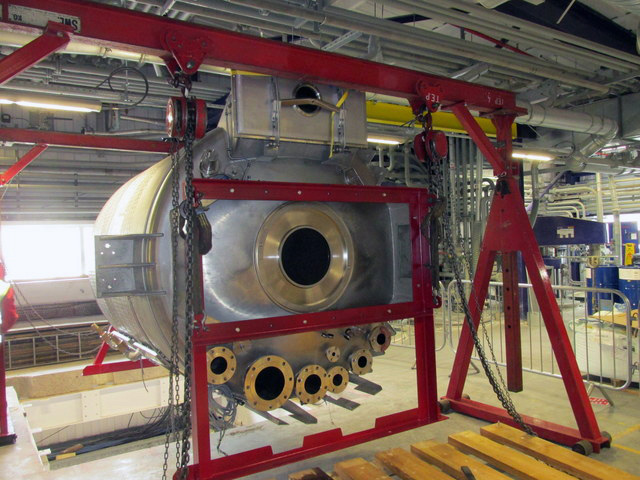

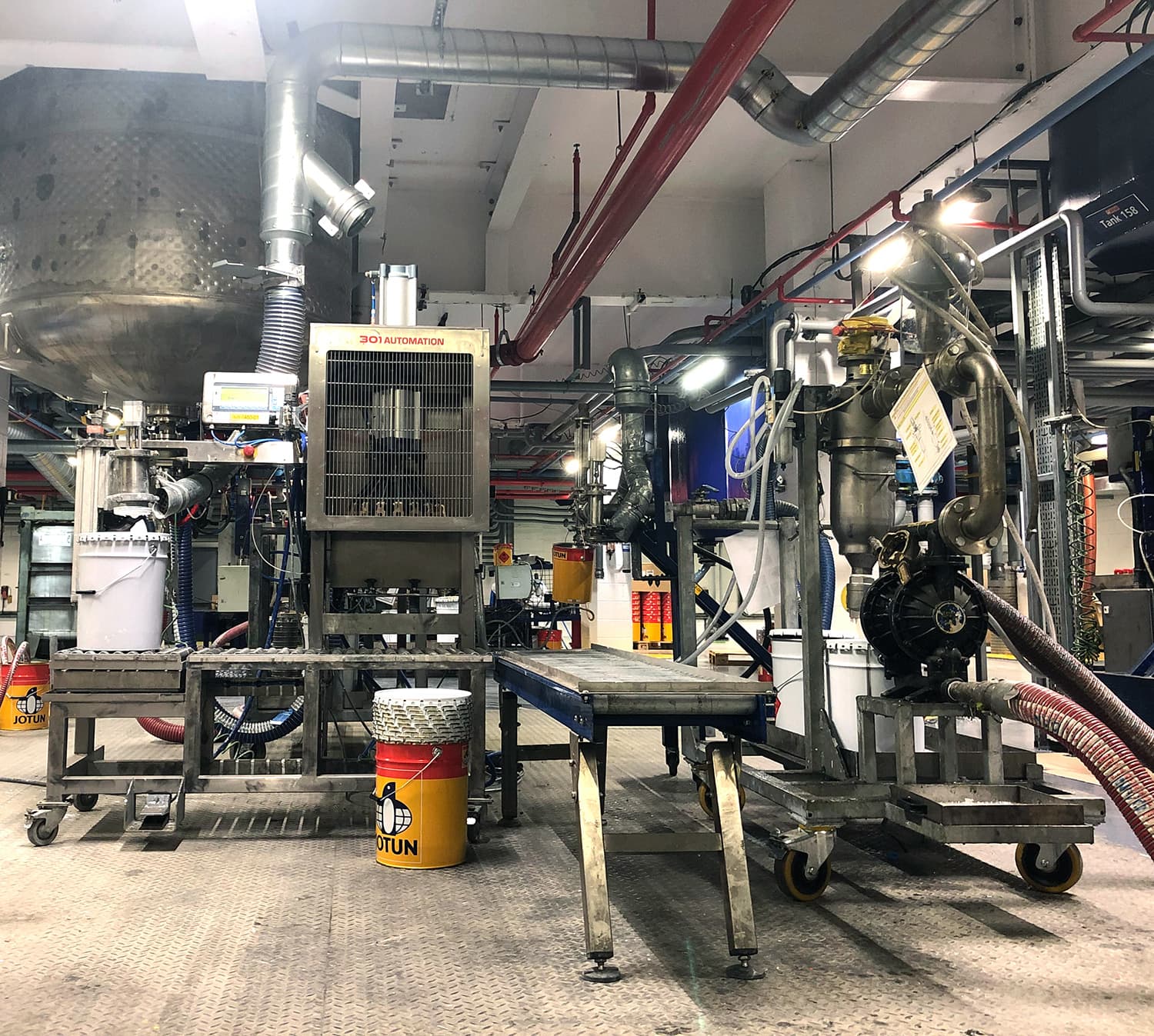

Design and install two bulk dispersion mixers and one bead including process infrastructure

Jotun Paints is one of the world’s leading manufacturers of decorative paints and protective coatings, with a presence in over 100 countries and 39 production facilities worldwide. Headquartered in Norway, the company serves key sectors including marine, industrial, infrastructure, and architectural markets. Renowned for technological innovation and uncompromising quality, Jotun coatings are trusted on everything from iconic skyscrapers to icebreaker ships operating in some of the planet’s harshest environments. The group’s global reach is matched by its local expertise, enabling responsive service and tailored solutions. With a strong commitment to sustainability and performance, Jotun sets the benchmark in coatings excellence.

Ai Process Scope of Works

- Conducted detailed site surveys and equipment measurements to prepare for mixer installation logistics

- Produced detailed design documentation including P&IDs, general arrangement drawings, and layout plans to define process integration and spatial requirements

- Equipment procurement, factory acceptance tests (FATs), and vendor quality assessment

- Coordinated full HAZOP studies, risk assessments, and method statements for ATEX compliance

- Supervised site installation, logistics, and contractor management within a confined operational space

- Commissioned equipment and delivered operator training to ensure smooth transition and operational continuity

Outcome and Benefits

1. Optimised Space Utilisation

Ai Process maximised the use of limited available floor space by producing detailed layouts and sequencing plans that enabled seamless integration of high-capacity equipment. The mixers and bead mill were successfully installed in a congested environment, eliminating the need for costly structural expansion or relocation—ensuring a lean, high-performing facility footprint.

2. Minimal Production Interruption

All works were carefully phased around Jotun’s live production schedule, allowing the plant to remain operational throughout. By coordinating contractors, deliveries, and shutdown windows with precision, Ai Process ensured that the new system was installed and commissioned with minimal impact to existing throughput—proving critical to maintaining supply commitments during the upgrade.

3. Improved Throughput & Precision

The new bulk dispersion mixers and bead mill significantly increased batch processing efficiency, improving mixing speed and consistency. Enhanced control systems and repeatable performance allowed Jotun to maintain tighter tolerances, reduce rework, and scale production more effectively—boosting capacity while improving the overall quality and reliability of finished products.

4. Rigorous Safety Compliance

Operating within an ATEX-rated zone required meticulous safety planning. Ai Process delivered the project to the highest safety standards, carrying out detailed risk assessments, HAZOP studies, and ATEX-compliant designs. All installation work was performed under strict controls, safeguarding personnel, plant assets, and the surrounding environment during and after commissioning.