Jotun

EPCM Contractor Ai Process Delivers R&D Facility Expansion to Enhance Testing Capabilities and Operational Efficiency for Jotun Paints (Europe) Ltd

Client:

Jotun

Industry:

Paints, inks & coatings

Project Site:

Flixborough, UK

Objective:

Design and deliver an advanced R&D facility expansion to enhance testing precision, safety, and scalability.

Jotun Paints is a global leader in the manufacture of decorative, protective, and intumescent coatings, with operations across 100 countries and 39 production plants worldwide. Renowned for its durable, high-performance paint systems—used on structures from offshore platforms to icebreaker ships—Jotun continues to lead innovation in protective coating technology.

At its Flixborough, UK site, Jotun undertakes critical research and development (R&D) activities for advanced coating systems. To maintain its competitive edge and strengthen product testing capability, the company commissioned Ai Process to deliver a turnkey expansion of its R&D facilities, combining technical design excellence with full regulatory compliance.

Ai Process Scope of Works

Operating as Principal Designer and EPCM Contractor, Ai Process provided full process engineering design and project management services for Jotun’s new R&D facility expansion. Scope included:

- Front-End Engineering Design (FEED) and detailed engineering for the full facility layout

- Preparation of User Requirement Specification (URS) and technical documentation

- Procurement management, construction supervision, and contractor coordination

- Expansion and fit-out of laboratories, offices, welfare areas, and warehouse zones

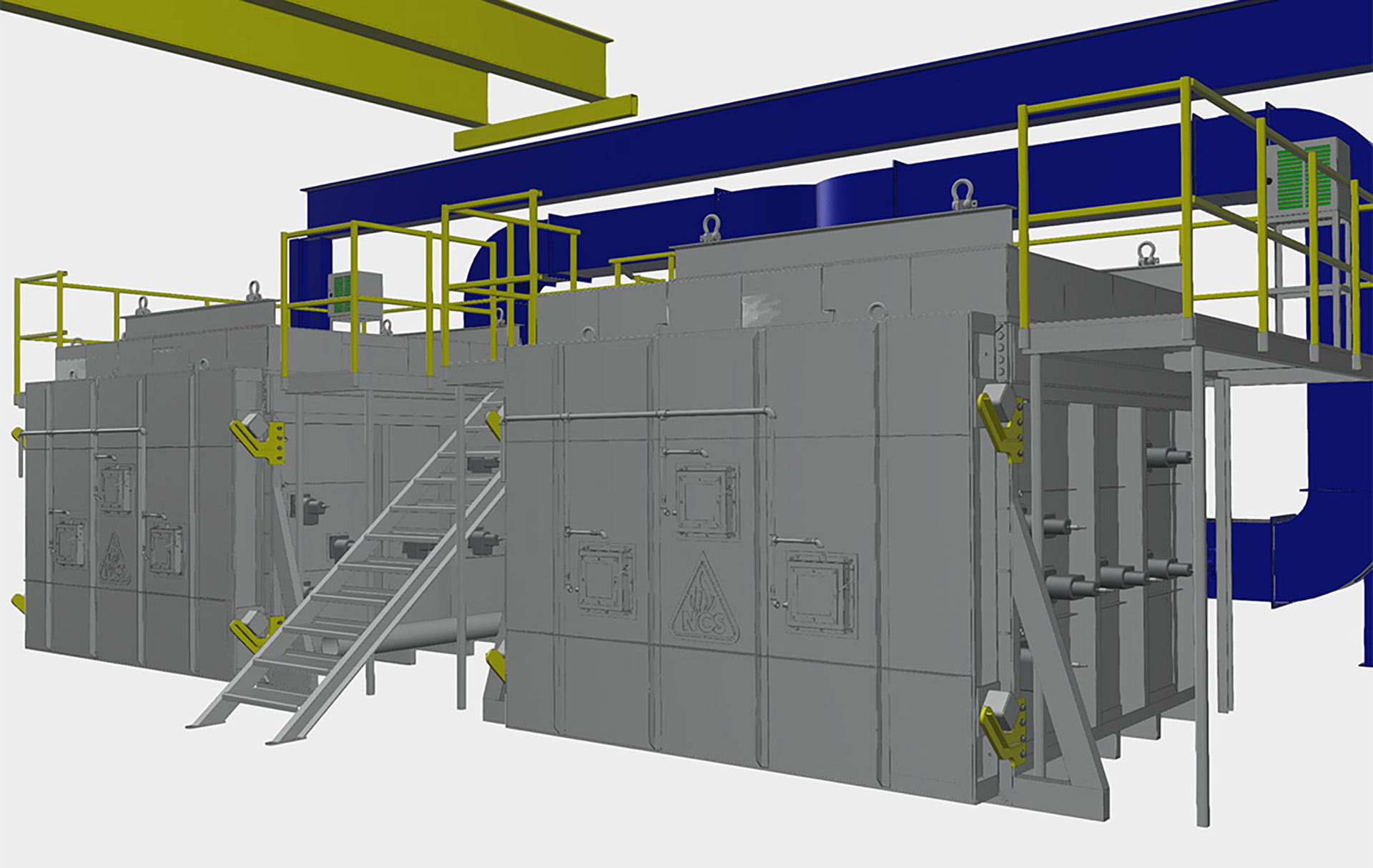

- Installation of twin high-temperature test furnaces with automated control systems

- Integration of process pipework, utilities, and instrumentation control

- Implementation of ATEX-compliant exhaust and filtration systems for fire safety

- Installation of a heavy-duty overhead crane for test handling and maintenance operations

Outcome & Benefits

Enhanced Testing Accuracy and Process Control

Ai Process engineered a state-of-the-art twin-furnace R&D test system, equipped with advanced automation, control, and monitoring technologies. This upgrade enables Jotun to perform more precise and repeatable test cycles, accelerating coating development and improving overall R&D efficiency—a key advantage in the highly competitive industrial coatings sector.

Modern Laboratory, Office & Welfare Facilities Improve Working Environment and Operational Standards

Ai Process delivered fully upgraded laboratories, offices, and staff welfare areas—including new changing rooms—creating a safer, more efficient, and more comfortable working environment for Jotun’s R&D team. The enhanced facilities support cleaner workflows, improved staff wellbeing, and higher operational standards, providing Jotun with a modern, professional setting that strengthens both productivity and compliance.

Streamlined Operations and Improved Productivity

Optimised layout planning, automated test sequences, and a new gantry crane system reduced manual handling, test setup time, and downtime between R&D runs. The design achieved a safer, more efficient workflow—directly addressing common industry pain points of operational bottlenecks, inefficient material movement, and safety-related process delays.

Future-Proofed and Scalable Infrastructure

As a trusted EPCM contractor and industrial process engineering specialist, Ai Process successfully delivered a high-specification R&D facility expansion for Jotun Paints (Europe) Ltd. The project integrated advanced testing technology, ATEX-compliant safety systems, and scalable infrastructure—enhancing testing precision, regulatory compliance, and operational efficiency. This turnkey project reinforces Jotun’s position as a global leader in coatings innovation.