Tor Coatings

Ai Process Design, Construct & Commission a New Solvent Tank Farm & Distribution System for RPM International Inc. subsidiary, Tor Coatings.

Client:

Tor Coatings

Industry:

Paints, inks & coatings

Project Site:

Birtley, UK

Objective:

Solvent tank farm construction

Tor Coatings is a leading UK manufacturer specialising in advanced interior and exterior building protection products. As a subsidiary of RPM International Inc., one of the world’s largest coatings groups, the company develops high-performance protective coatings designed to enhance the longevity and safety of buildings. Tor Coatings is best known for its flame-retardant coatings, which provide critical fire protection, as well as its liquid roofing systems, anti-graffiti solutions, and corrosion-resistant coatings. The company also manufactures and distributes Rust-Oleum products in the UK, offering industry-leading solutions for surface protection, maintenance, and restoration across commercial and industrial sectors.

Ai Process Scope of Works

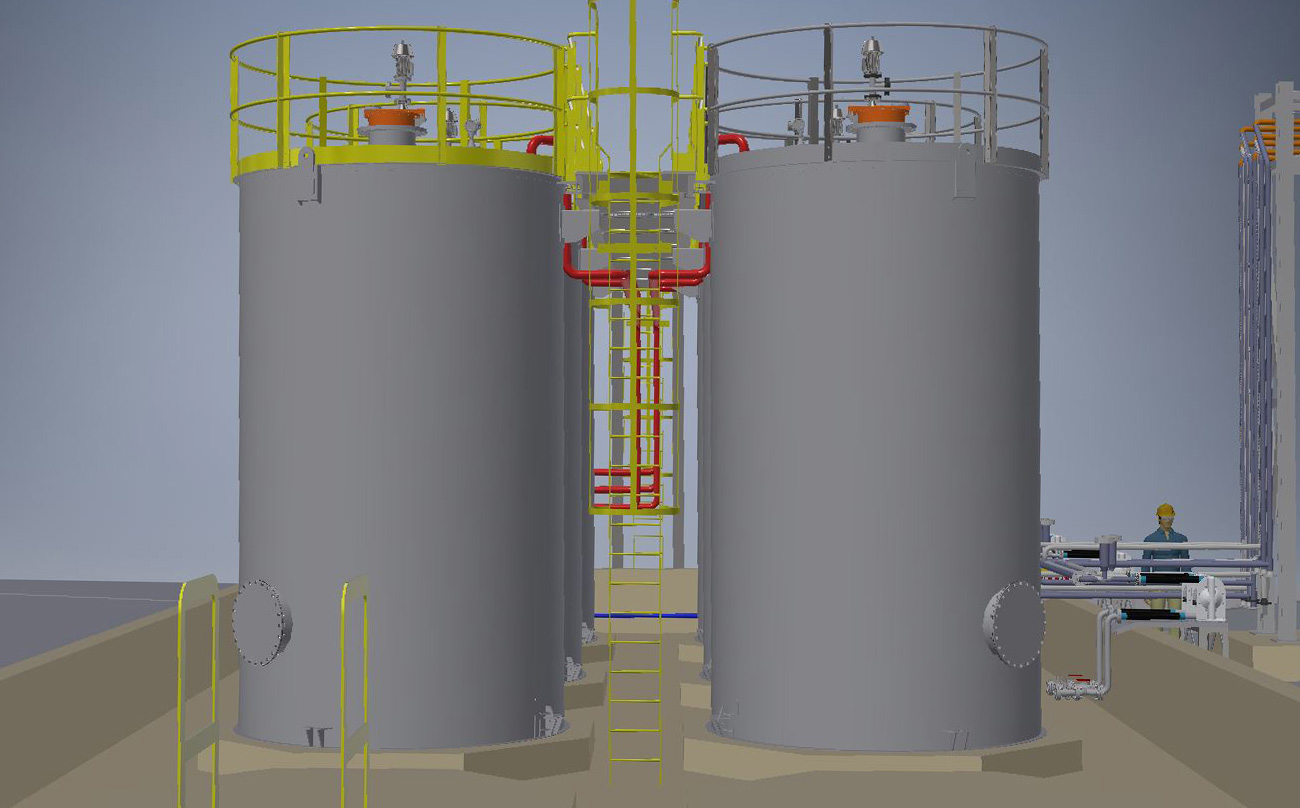

- FEED study: 3D models, P&IDs, general arrangement layouts, equipment specs, and procurement

- Demolition and removal of existing lowflash and highflash tanks

- Design and construction of bunded tank farm site

- Installation of six 30,000 L solvent storage vessels

- Comprehensive process infrastructure: pumps, valves, pipework, instrumentation, electrical systems, and process control

- Pipe bridge connection to main manufacturing facility

- Safety systems: VOC gas detection, bund sprinkler, and tanker loading area protection

Outcome and Benefits

1. Increased Storage Capacity and Scalability

The new tank farm provides Tor Coatings with a significantly larger and more efficient storage solution. With six 30,000-litre vessels installed and infrastructure designed to accommodate four additional vessels in the future, Tor Coatings has the flexibility to scale production as demand grows, ensuring long-term operational efficiency.

2. Enhanced Health, Safety, and Environmental Compliance

The new bund design ensures proper containment in case of spills, protecting both workers and the environment. Upgraded process safety measures, including fire protection and vapor control, ensure compliance with stringent health, safety, and environmental regulations. ATEXrated design, VOC detection, and sprinkler systems improved site safety and regulatory compliance.

3. Zero Disruption to Manufacturing Operations

Ai Process coordinated phased demolition, tank replacement, and integration activities to allow uninterrupted solvent handling and distribution throughout the project. This careful planning ensured no downtime for Tor Coatings’ production teams and preserved manufacturing throughput during the entire construction period.

4. Full Compliance with HSG 176 and ATEX Safety Standards

The tank farm was designed and constructed in compliance with HSG 176 guidance for storage of flammable liquids, including appropriate vessel spacing, fire containment, and ignition source control. Combined with ATEX-rated equipment, the installation delivers safe handling of hazardous materials and regulatory peace of mind.