Vil Resins

Ai Process Design, Construct & Commission New Oils Tank Farm and Transfer System for VIL Resins Ltd in Bolton

Client:

VIL Resins

Industry:

Coatings & resins

Project Site:

Bolton, UK

Objective:

Design, construct, and commission new oils tank farm and transfer system

VIL Resins Ltd is a family-owned manufacturer based in Lancashire, England, with over 80 years of experience producing high-performance resins for coatings, adhesives, and composites. Supplying both domestic and international markets, VIL Resins has developed extensive technical knowhow and industry expertise. The company is recognised for quality, consistency, and innovation in resin production, continually investing in infrastructure and processes to meet evolving regulatory standards and customer demand.

Ai Process Scope of Works

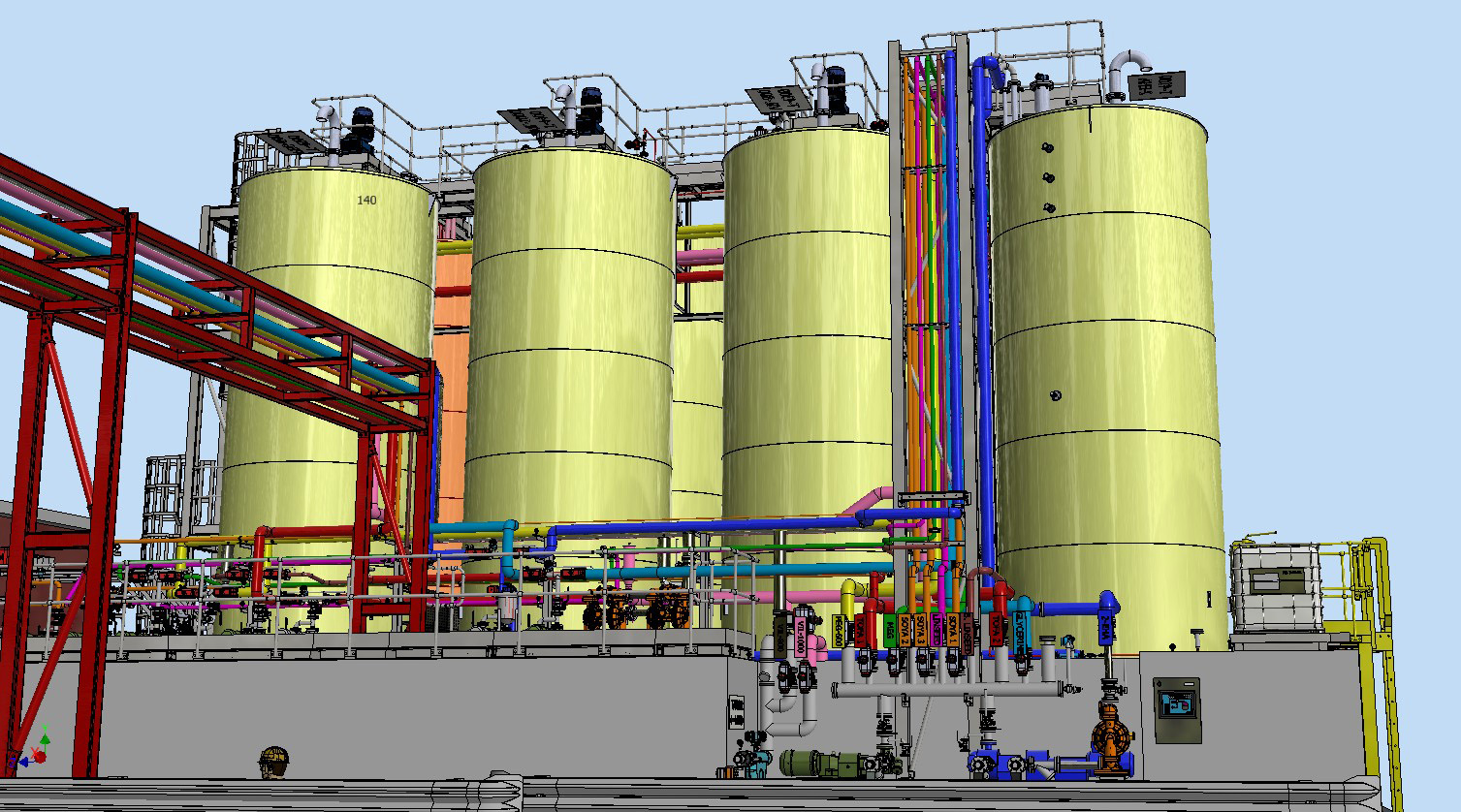

- Front-End Engineering Design (FEED) study, including 3D modelling, P&IDs, and general arrangement layouts

- Civil works and bund construction for oil storage compliance

- Design, procurement, and installation of 13 × 60,000 L oils storage tanks

- Construction of a transfer pipe bridge connecting the tank farm to the main facility

- Integration of process infrastructure including pipework, pumps, valves, instrumentation, and process control system

- Full process integration of new tank farm with existing manufacturing operations

- Turnkey project delivery: detailed engineering, procurement, construction, process testing, and commissioning

Outcome & Benefits

Increased Bulk Storage Capacity

Ai Process delivered 13 large-scale oil storage tanks, significantly expanding VIL Resins’ bulk storage capability. This upgrade eliminated labour-intensive IBC handling, allowed higher raw material volumes, reduced supply chain interruptions, and strengthened overall operational resilience at the Bolton facility.

Enhanced Safety & Regulatory Compliance

Although not an ATEX installation, the tank farm was designed to meet stringent UK standards for hazardous materials storage, including robust bunding, spill containment, and overfill protection. The design strengthens environmental protection, reduces risk, and provides VIL Resins with long-term regulatory confidence.

Optimised Process Integration & Workflow Efficiency

By seamlessly integrating new tanks with existing plant infrastructure, including pumps, valves, and pipework, Ai Process reduced manual handling, minimised process bottlenecks, and improved material flow. Operators now benefit from safer, faster, and more reliable transfer operations.

Future-Proofed & Scalable Infrastructure

The tank farm was designed to accommodate future expansion and increased production demand. Modular pipework, service infrastructure, and capacity for additional storage ensure long-term scalability, giving VIL Resins the flexibility to grow without major capital disruption.