VIL Resins

20,000 L Resin Reactor & Process Upgrade Accelerates Production for VIL Resins Ltd

Client:

VIL Resins

Industry:

Adhesives & resins

Project Site:

Bolton, UK

Objective:

Design, install and commission a 20,000 litre resin reactor including process infrastructure

VIL Resins are an independent family-owned manufacturing company based in Lancashire, England. They have been successfully manufacturing surface coating resins for over 80 years and, as a consequence, have developed unique knowhow and industry knowledge in resin production. Throughout the many years of operation, VIL Resins have manufactured and supplied resins to UK and international markets. They are a leading manufacturer of high-performance resins used in coatings, adhesives, and composites.

Ai Process Scope of Works

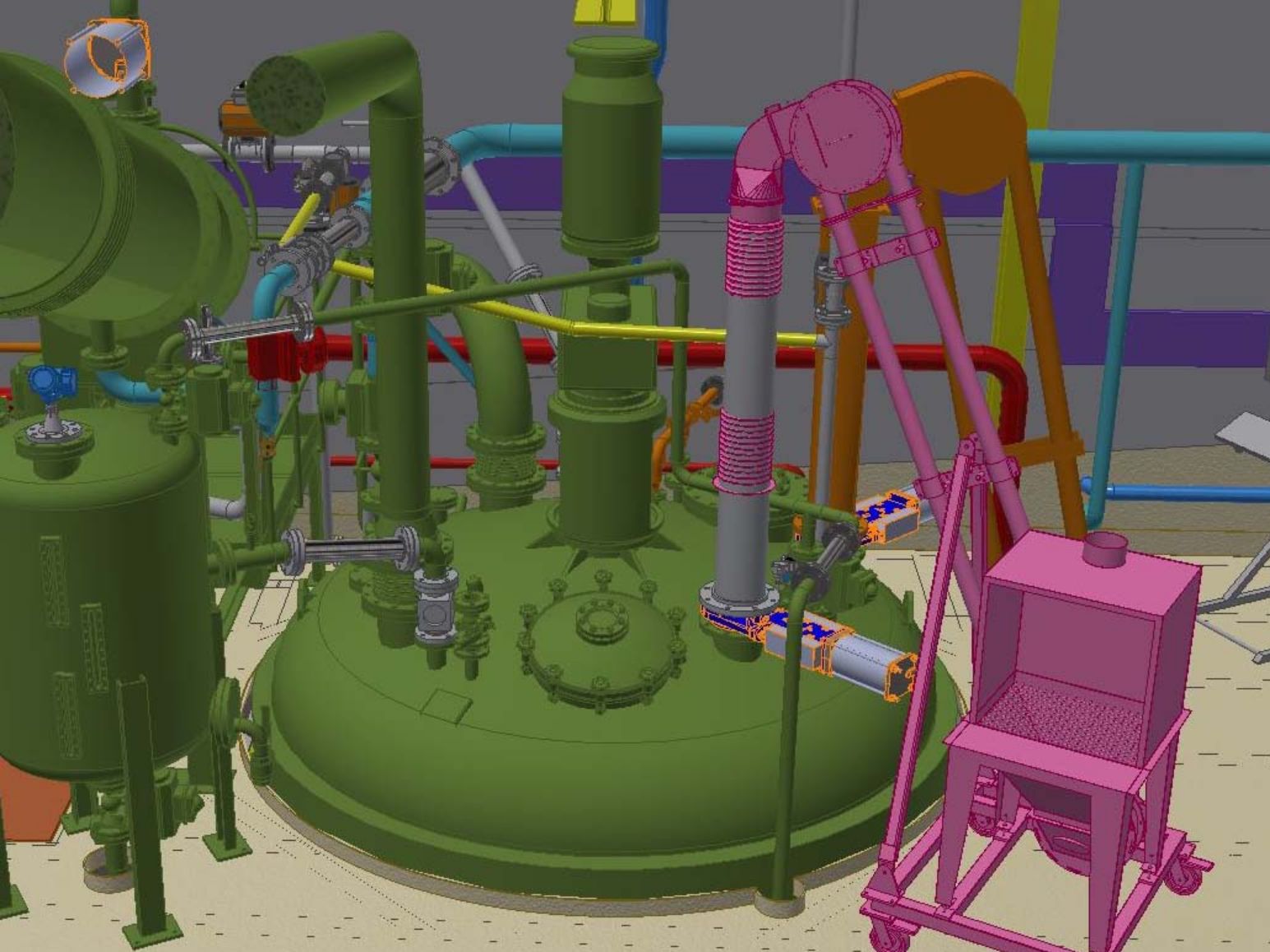

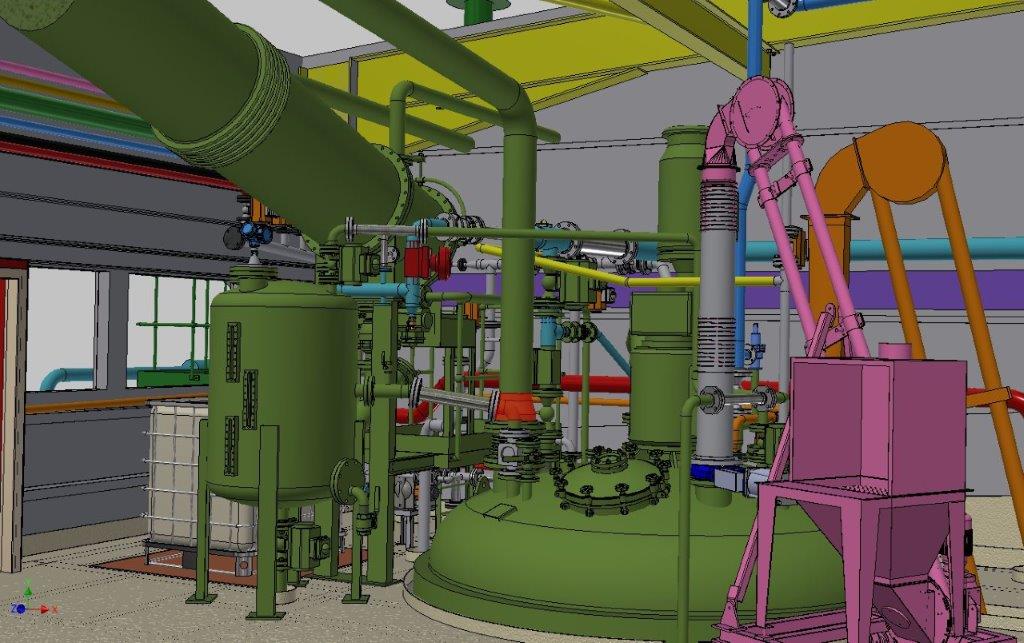

- FEED study: 3D modelling, P&ID drawings, general arrangement layout, equipment specifications and costing

- Detailed engineering, procurement, installation, and commissioning of:

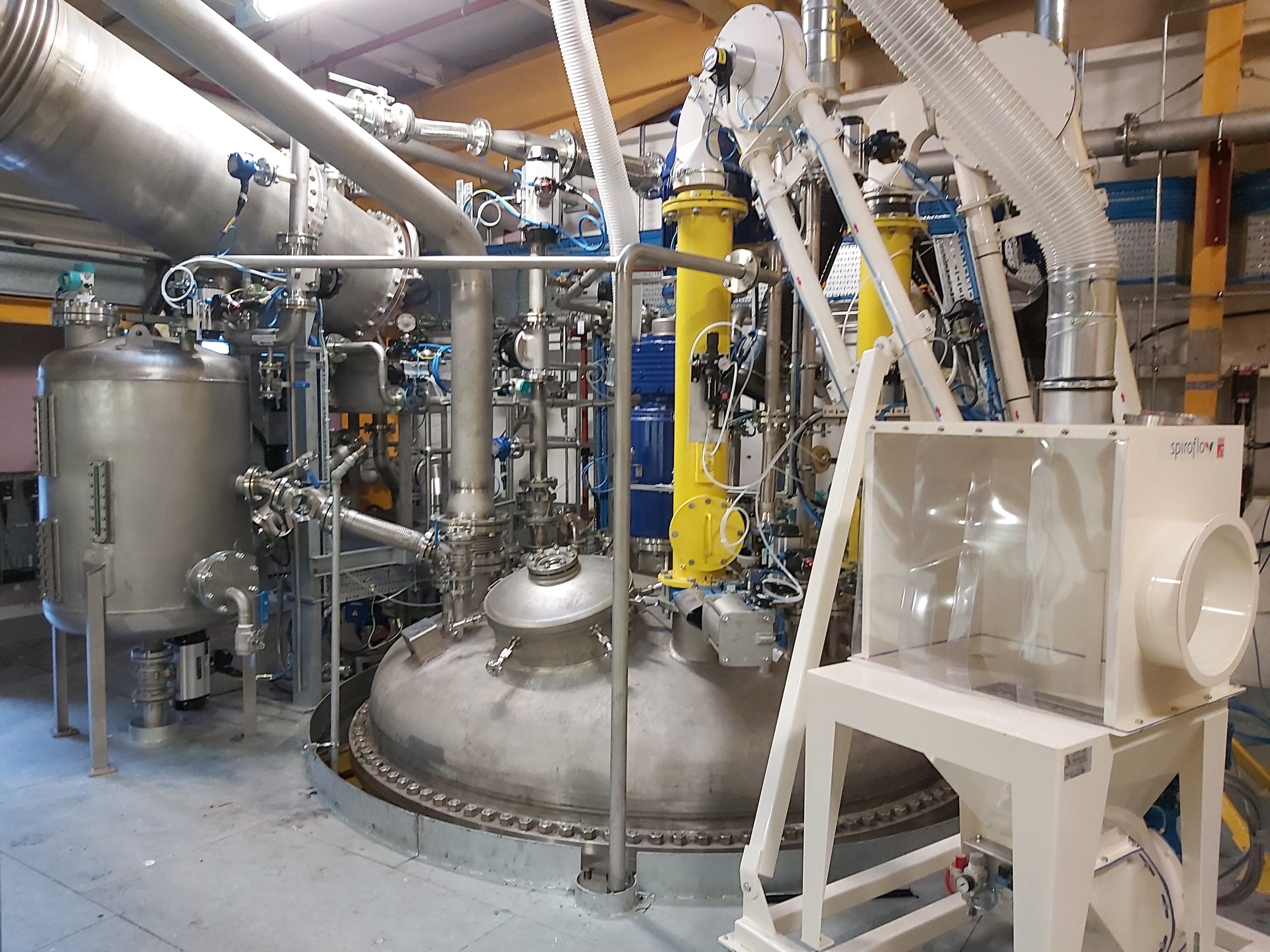

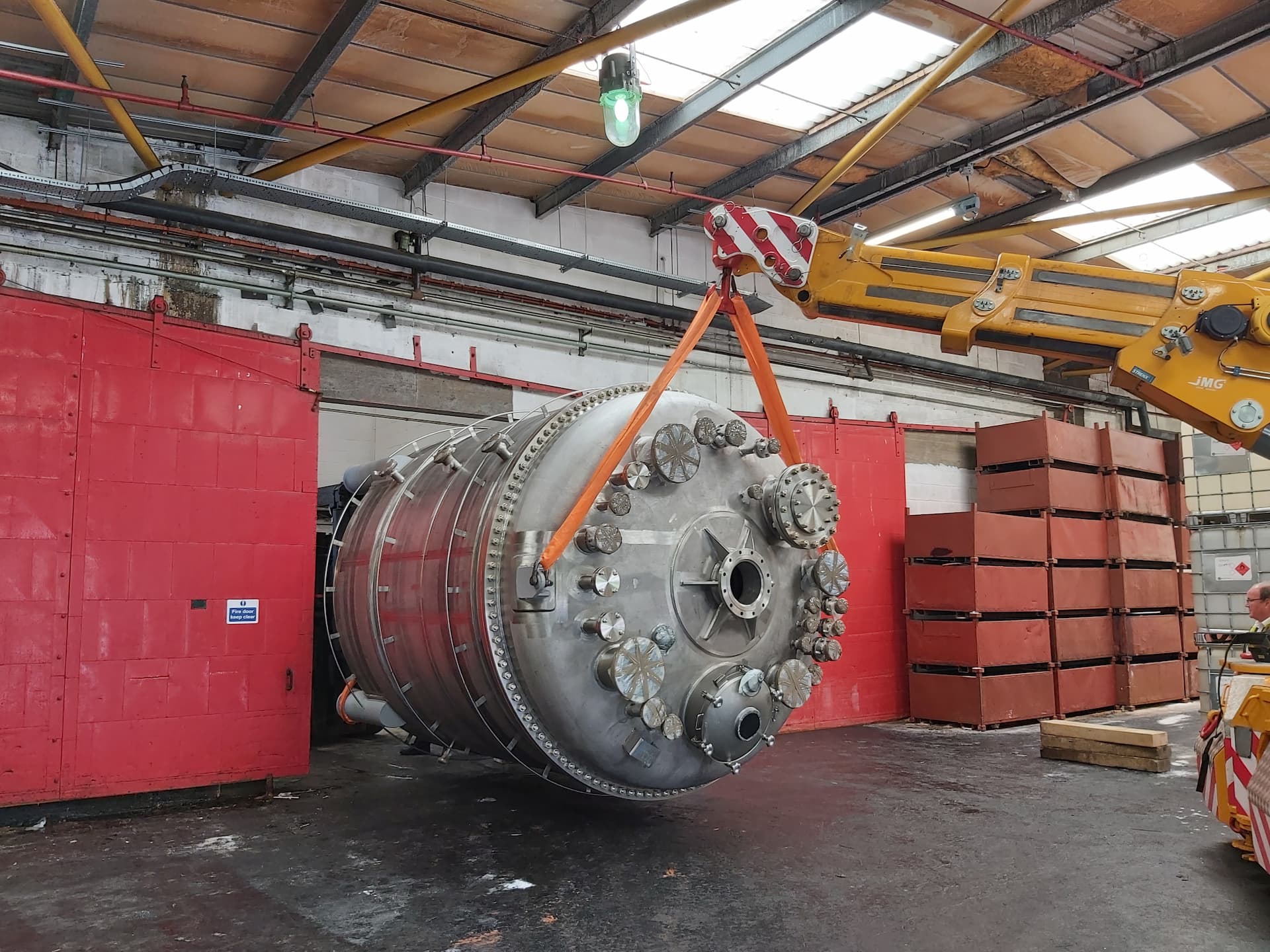

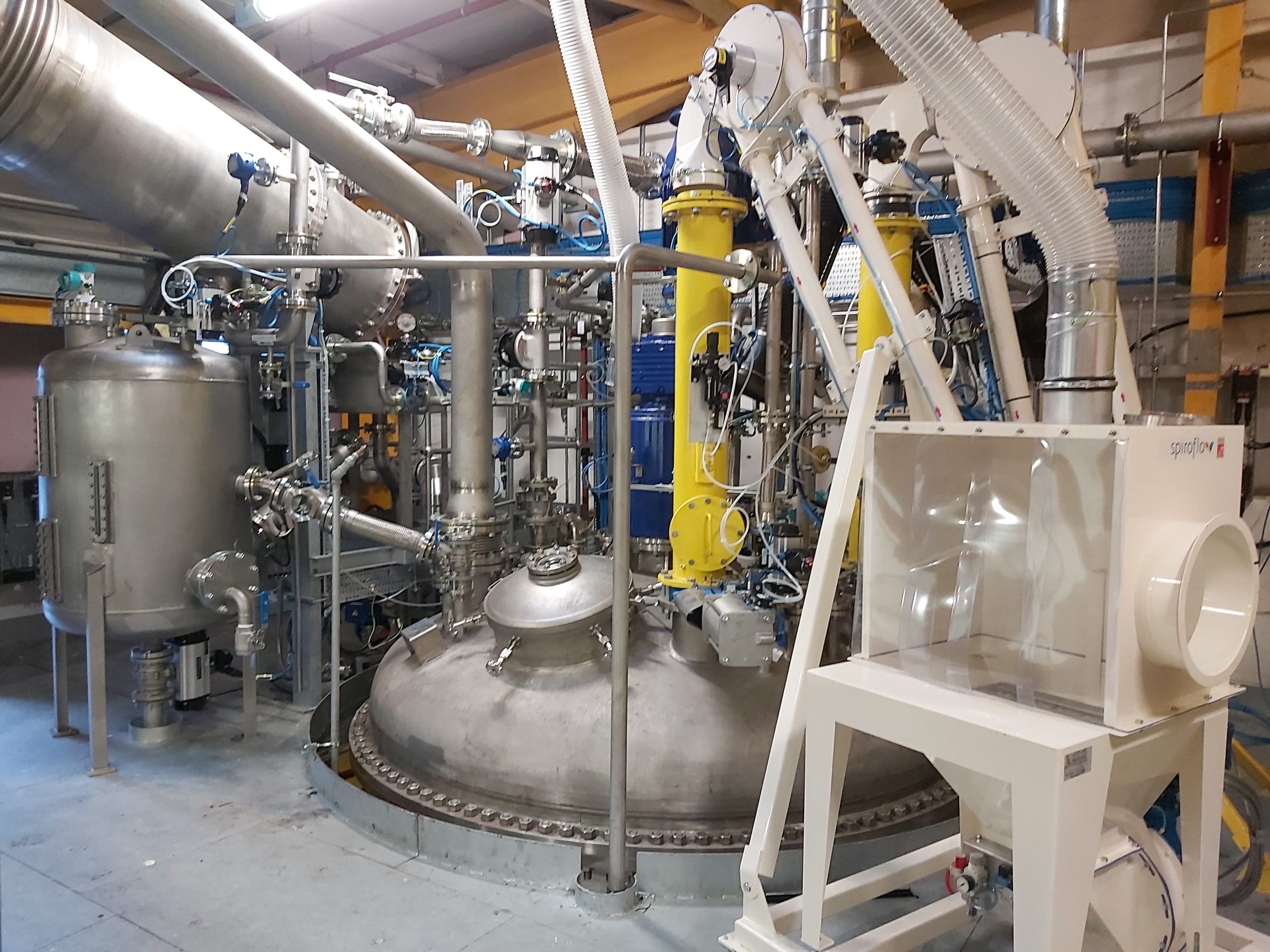

- 20,000 L resin reactor and condenser

- Phase separator, charge tank, powder handling system

- Structural steel mezzanine for operator access/process control room

- Process and service pipework, instrumentation, electrical installation

- Hot oil boiler system, ground tank, environmental extraction systems

- Civil and building works supporting integrated installation

Outcome & Benefits

1. Significant Capacity Uplift

The newly installed 20,000 litre resin reactor, along with its supporting infrastructure, significantly increased VIL Resins’ production output. This uplift enables the business to meet growing demand across both domestic and export markets.

2. Optimised Raw Material Utilisation & Waste Reduction

Refinements in resin processing and reactor performance helped reduce raw material waste, lower batch variability, and improve yield—resulting in operational cost savings and more sustainable manufacturing.

3. Optimised Plant Layout in Tight Footprint

The new mezzanine-level layout maximised limited site space, enabling Ai Process to install a large-scale reactor and associated systems without expanding the facility footprint. This efficient use of vertical space also improved workflow, operator access, and process visibility.

4. Resilience Amid Pandemic Pressures

Despite global supply chain disruptions and labour constraints during the COVID-19 pandemic, Ai Process delivered the project on time and within budget—demonstrating proactive logistics, strong supplier coordination, and agile project execution.